Table of Contents

When you hear ‘lithium,’ your mind probably jumps straight to electric vehicles and the batteries powering our sustainable future. But what if we told you that this versatile element is quietly revolutionizing industries far beyond the automotive world?

From fortifying our defense systems to ensuring the seamless operation of global data networks and even enhancing everyday medical devices, lithium’s unique properties are unlocking a new era of industrial innovation in 2025 and beyond. Prepare to discover the surprising and indispensable roles lithium plays in a diverse range of critical sectors, proving its worth extends far beyond the EV charging port.

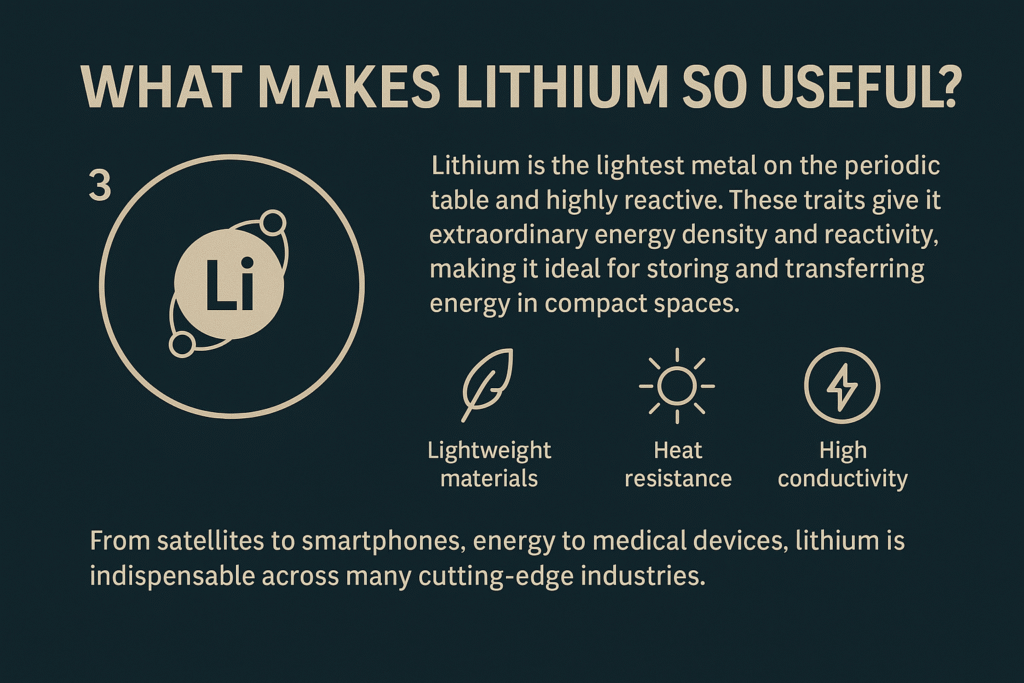

What Makes Lithium So Useful?

Lithium is the lightest metal on the periodic table — just three protons, a high electrochemical potential, and a tendency to shed electrons easily. These traits give it extraordinary energy density and reactivity, making it ideal for storing and transferring energy in compact spaces.

Its low atomic weight allows for lightweight materials and components, while its heat resistance and conductivity enable high-performance applications in electronics, aerospace, and medical devices. It’s one of the few elements that plays equally well in both cutting-edge industries and traditional manufacturing — from satellites to smartphones, from ceramics to surgical implants.

That rare versatility, more than any single use case, is what makes lithium indispensable across energy, defense, telecom, and industrial automation. In short, lithium isn’t just useful it’s foundational to how modern infrastructure functions. This article explores six e emerging non-EV industrial uses of lithium that are set to shape the future demand for this “white gold.

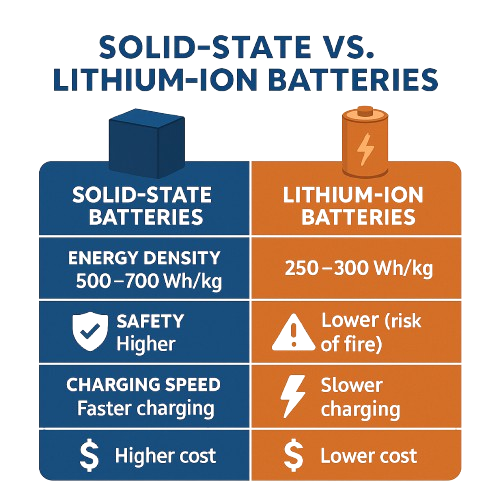

Solid-State Batteries and Advanced Energy Storage

Solid-state batteries represent the next leap in energy storage. Unlike conventional lithium-ion cells that use flammable liquid electrolytes, solid-state batteries rely on ceramic or polymer-based solid electrolytes. This design increases safety, enhances energy density, and extends the battery’s usable life.

Recent research indicates that solid-state lithium batteries have the potential to deliver energy densities exceeding 400 Wh/kg, compared to 250–300 Wh/kg for traditional lithium-ion cells. This advancement could enable devices to last longer on a single charge while reducing overall system size and thermal management requirements.

Major global players like Toyota and QuantumScape are actively investing in this space. In India, institutions such as BHEL and ISRO are exploring applications for satellite payloads and grid-scale energy storage, reinforcing lithium’s central role in next-generation battery innovation.

Key Takeaway: Solid-state batteries may double the performance of traditional batteries — and lithium remains at the heart of this transformation.

Lithium for Data Centers and Grid Backup

Data centers and hyperscale computing facilities are the silent backbone of the digital economy. These infrastructure giants demand round-the-clock power with ultra-low failure rates. Lithium battery packs are increasingly replacing traditional lead-acid UPS systems due to their long cycle life (up to 6,000 cycles), fast recharge, and compact design.

In UPS applications, lithium systems offer energy densities of 150–200 Wh/kg and recharge times as low as 30 minutes. Additionally, they help reduce data center cooling needs by 10–20% due to lower heat output.

In grid applications, lithium batteries support load balancing, peak shaving, and storage of renewable power. Tesla’s Megapack and Fluence’s grid-scale solutions are already used globally, offering scalable capacity from 3 MWh to 100+ MWh systems.

Key Takeaway: Lithium batteries now power both your social media and your electricity grid.

Lithium in Wearables and Smart Medical Devices

Lithium-polymer batteries have enabled an explosion of innovation in wearables and healthcare. These batteries are thin, flexible, and energy-dense—perfect for devices that must be light, long-lasting, and ergonomic.

Modern lithium-polymer cells used in wearables operate at 3.7V, offer up to 500 cycles, and come in ultra-thin formats as small as 0.5 mm. Battery capacities typically range from 40 mAh (fitness bands) to 300+ mAh (smartwatches).

Today’s lithium-powered wearables include:

- Fitness trackers and smartwatches

- Continuous glucose monitors (CGMs)

- Portable ECG machines

- Smart medical implants (e.g., cardiac monitors, neurostimulators)

- Automated External Defibrillators (AEDs), where lithium cells deliver 150–360 joules per discharge over 100+ cycles

Key Takeaway: Lithium keeps your smartwatch alive—and your pacemaker too.

Defense, Tactical, and Aerospace Applications

Lithium’s high energy density and light weight make it ideal for use in field-deployable military hardware. In tactical scenarios, lithium batteries power:

- Drones and unmanned aerial vehicles (UAVs)

- Portable radar and communication kits

- Night vision and thermal gear

- Satellite electronics

In military drones, lithium battery packs provide energy densities of 180–250 Wh/kg and support flight durations of up to 2–3 hours. Rugged lithium packs also operate effectively in temperature ranges from –40°C to +60°C.

Key Takeaway: From border surveillance to space tech, lithium is becoming a strategic military asset.

Industrial Automation and Robotics

In Industry 4.0 ecosystems, lithium-ion batteries fuel automation across warehouses, factories, and supply chains. Automated Guided Vehicles (AGVs), robotic arms, and precision tools require uninterrupted energy with minimal downtime.

Industrial lithium batteries can deliver over 3,000 cycles and reduce charging time by 30–50% compared to lead-acid alternatives. High-performance systems can operate with round-the-clock duty cycles and need just 1–2 hours to fully recharge.

Key Takeaway: Industrial robots run longer, faster, and cooler on lithium.

Industrial and Specialized Lithium Applications

Glass and Ceramic Manufacturing

Glass and ceramics rely heavily on lithium compounds as vital additives that create stronger, more durable products. Lithium carbonate or spodumene addition lowers firing temperatures and reduces thermal expansion and energy consumption during manufacturing. The temperature reduction brings substantial benefits to production, including longer equipment life, higher yields, and better operating conditions.

Lithium-bearing materials give glass several improved properties. The material’s durability, corrosion resistance, and thermal shock resistance make it perfect for modern applications. These features have made lithium-infused glass the ideal choice for smartphones, cooktops, and building materials. Glass and ceramics manufacturing claimed about 22% of global lithium consumption in 2019, ranking as the second-largest lithium-consuming industry after rechargeable batteries.

Grease and Lubrication Industry

Lithium-based greases stand out because of their exceptional versatility and performance. These greases maintain consistent viscosity in extreme temperatures (–60°C to 300°C) and resist water even in tough conditions. The automotive industry, mining operations, and construction equipment benefit from these properties.

- Mining and metal production

- Electric motors and ball bearings

- Construction and agricultural equipment

- Automotive components and water pumps

White lithium grease excels at protecting components from water while lubricating hard-to-reach areas.

Metallurgical Enhancements

Lithium acts as a purifying agent in metallurgy through deoxidation and degasification processes. It attracts nonmetallic particles from refined metals like iron, zinc, copper, and nickel. Aluminum becomes remarkably strong when combined with lithium, creating alloys as strong as some steels but much lighter. Aircraft manufacturers prefer these lithium-aluminum alloys for their exceptional strength-to-weight ratio.

Air Purification and HVAC Systems

Lithium chloride solutions work as powerful non-toxic disinfectants in air conditioning systems. Research shows they remove 87.3% of airborne fungi and 72.4–81.3% of bacteria. This happens because lithium captures bioaerosols without forming condensate water where harmful microbes typically thrive.

Lithium hydroxide monohydrate is used to scrub CO₂ from the air, binding carbon dioxide through chemisorption into lithium carbonate and water. Similarly, lithium bromide absorbs water vapor efficiently, making it a key component in HVAC absorption chillers.

Medical and Safety Uses of Lithium

Pacemakers and Implantable Devices

Lithium-iodine batteries revolutionized cardiac implantable electronic devices (CIEDs) starting in 1972. These power sources have proven extremely reliable, with a 99.6% survival rate beyond 8 years. Modern pacemaker batteries provide 7–8 years of service while weighing less than 30 grams and occupying just 5–8 cc of volume.

Portable Medical Equipment

Bone growth stimulators, glucose monitors, and AEDs all rely on lithium batteries for their high energy density and pulse power. These batteries meet stringent safety standards while ensuring long-term performance without using toxic materials.

Surveillance and Alarm Systems

Lithium batteries are ideal for outdoor and long-term safety systems. They lose less than 2% charge per year and can operate across –30°C to 70°C. Quality batteries meet international certifications such as UL, UN38.3, and IEC62133 and often include smart battery management systems to prevent overcharging, deep discharge, or short circuits.

Key Takeaway: From smartphones to pacemakers, greases to HVAC—lithium’s real-world impact spans every sector of modern life, backed by measurable performance stats.

What This Means for India

While India has identified lithium reserves in Jammu & Kashmir and Rajasthan, it still lacks refining, separation, and downstream processing capabilities. Most of the lithium used in these emerging sectors will continue to rely on imports in the near term.

Government initiatives like the National Critical Minerals Mission (NCMM), Khanij Bidesh India Ltd. (KABIL), and urban mining programs are steps in the right direction. But unless India accelerates its midstream infrastructure, it risks becoming dependent in precisely the industries it seeks to lead.

Conclusion

Lithium has quietly become the backbone of modern industry — powering smartphones, medical implants, smart factories, and clean energy systems. Beyond batteries, it strengthens aircraft alloys, purifies air in HVAC systems, and supports next-gen automation.

Global demand is set to quadruple by 2030. Yet India remains heavily import-dependent, with no commercial refining or processing yet in place. Strategic missions like NCMM and KABIL mark a shift, but scaling infrastructure is urgent.

The Lithium Triangle‘s importance cannot be overlooked with its 75% share of known reserves. The need for lithium will quadruple by 2030, and access to this vital resource will shape industrial and economic landscapes for decades.

Battery applications lead today’s lithium conversation. Yet this metal’s varied uses across multiple sectors prove its irreplaceable role in advancing technology, sustainability, and healthcare. Despite sourcing and recycling challenges, lithium will remain the life-blood material that powers our future innovations well beyond 2025.

To explore how other critical minerals are reshaping India’s economy and industrial future, read our full breakdown of India’s 30 critical minerals.

FAQs

-

What are the lesser-known uses of lithium?

Lithium isn’t just powering electric vehicles — it’s also critical to industries like glass and ceramics, where it improves thermal resistance and durability. In fact, this sector consumed about 22% of the world’s lithium in 2019. Lithium is also used in greases for heavy machinery, air purification systems in HVAC units, and even in life-saving medical implants like pacemakers and defibrillators.

-

How is lithium used in data centers and AI infrastructure?

Modern data centers rely on lithium battery packs for uninterrupted power supply (UPS). These batteries recharge quickly, last for thousands of cycles, and reduce the cooling load thanks to their thermal efficiency. They’re increasingly being used to power AI server clusters and grid-scale backup systems, with solutions already deployed by Tesla, Fluence, and others..

-

Can lithium batteries support defense and aerospace operations?

Yes, and they already do. Lithium powers field-ready military drones, portable communications kits, and surveillance tools that must perform in extreme temperatures — from –40°C in high altitudes to over 60°C in desert conditions. India’s DRDO and ISRO have both used lithium battery systems in defense and space missions.

-

Why is lithium critical to India’s industrial strategy?

India’s ambitions in renewable energy, EVs, and electronics depend heavily on lithium. The country plans to install 500 GW of non-fossil capacity by 2030 and localize battery manufacturing — but it currently has no commercial lithium refining capacity and relies entirely on imports. That makes lithium not just a material need, but a strategic vulnerability.

-

Is lithium recycling a viable long-term solution?

It’s promising but still developing. Companies like Attero and Lohum are recovering lithium from old batteries and electronics in India, but recycling rates remain modest — often below 60%. As more EVs and devices enter the waste stream, lithium recovery through urban mining will play a key role in supply chain resilience, provided the infrastructure scales up.