Table of Contents

Introduction

Forget gold and lithium — one of the rarest and most essential elements in today’s technology is something lighter, stronger, and far more specialised. It’s beryllium: a silvery metal quietly driving breakthroughs in everything from satellite optics to X-ray machines.

Beryllium uses span a range of industries—medical imaging, aerospace systems, defence electronics, and high-performance alloys, where precision and reliability are non-negotiable.

Despite being one of the least talked-about elements, beryllium plays an outsized role in modern technology, quietly empowering industries that demand high-performance materials.

Lightweight yet remarkably strong, thermally conductive yet stable, beryllium’s properties are unlike any other element. That versatility enables beryllium to quietly power everything from flame-retardant plastics to precision alloys and medical compounds, often without being noticed by the end user.

India’s 2023 list of critical minerals places beryllium squarely in the spotlight, not just for its economic value but for its strategic role in defence, aerospace, electronics, and nuclear programmes. The stakes are high, and supply is tight. To truly understand why beryllium matters, we must look at what makes it unique, where it comes from, and how it shapes the world we live in.

Elemental Profile: What Makes Beryllium Unique

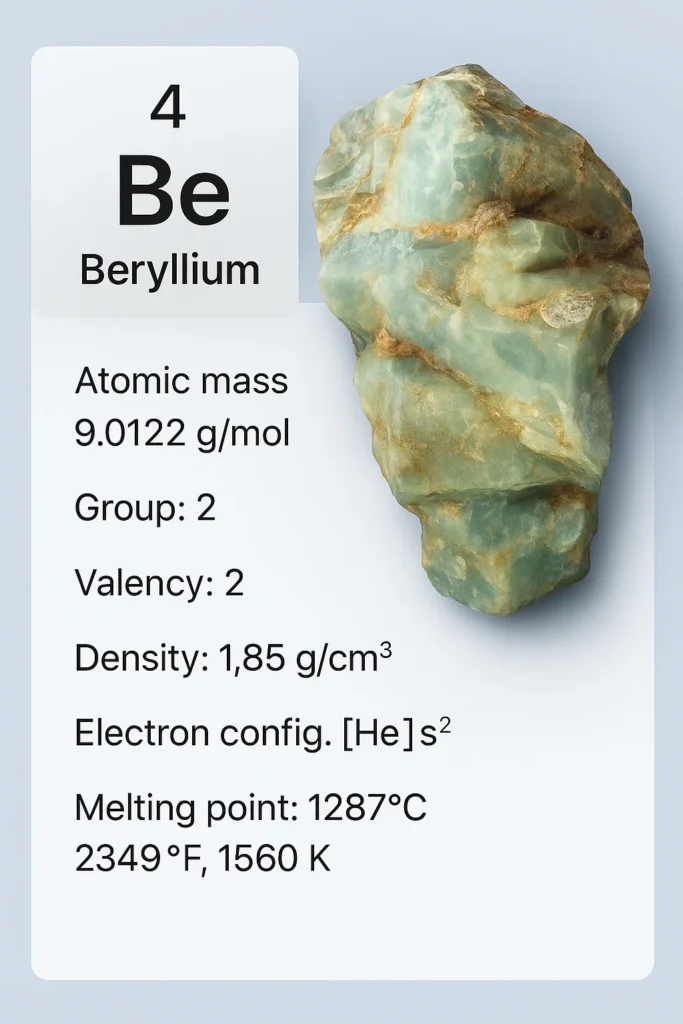

Beryllium (chemical symbol Be, atomic number 4) may be small on the periodic table, but its properties pack a serious punch. It is one of the rarest elements in Earth’s crust, occurring at an average concentration of just 0.0002% by weight (2 ppm).

Unlike more common industrial metals, it’s not found in pure metallic form. Instead, it occurs in trace amounts within mineral ores. This scarcity contributes to its classification as both a critical and strategic mineral in many countries, particularly for defence, aerospace, and nuclear sectors, where substitution is extremely difficult.

- Beryl (Be₃Al₂Si₆O₁₈): A hexagonal crystal also found in gemstones like emerald and aquamarine.

- Bertrandite (Be₄Si₂O₇(OH)₂): A softer, more abundant ore that has become the world’s primary source of industrial beryllium.

- Phenakite (Be₂SiO₄): Though rare, it is the richest known beryllium mineral, containing up to 46 wt% BeO in its purest form.

While beryl is more widely known, bertrandite dominates industrial supply due to easier processing and higher availability — especially in the U.S.

Beryllium ores are generally lean, with BeO concentrations ranging from 0.03% to 2%, depending on the deposit and method of extraction. This low yield increases both extraction costs and the mineral’s strategic value.

Is Beryllium a Metal or Nonmetal?

Beryllium is a Group 2 alkaline earth metal, sharing its family with magnesium and calcium, but it stands apart. Its stiffness is far greater, and its density much lower. Yet its traits defy typical metallic behaviour.

It doesn’t spark when struck, barely corrodes, and responds unusually to heat and radiation. These unique traits make it invaluable in aerospace, nuclear, and electronic systems.

Exceptional Stiffness-to-Weight Ratio

Beryllium has the highest specific stiffness of any metal — nearly six times that of steel, while being lighter than aluminium. This remarkable combination comes from its hexagonal close-packed (HCP) crystal structure and strong interatomic bonds.

Its modulus of elasticity reaches approximately 287 GPa, about one-third higher than steel, with a density of just 1.85 g/cm³.

These properties enable components that minimise weight without sacrificing structural integrity, enhancing fuel efficiency and mechanical performance in high-end systems. However, beryllium is brittle by conventional standards, exhibiting only ~2–4% tensile elongation at room temperature.

These same characteristics also make beryllium a preferred alloying element in lightweight structural materials like beryllium–aluminium (Be–Al) and beryllium–magnesium (Be–Mg), widely used in aerospace and defence castings for their stiffness and dimensional stability.

High Melting Point and Thermal Stability

At 1287°C, beryllium boasts the highest melting point among light metals. It keeps its structural integrity in extreme thermal environments without warping or losing essential properties , a critical factor for high-performance applications.

Excellent Thermal Conductivity

Beryllium’s thermal conductivity (~216 W/m·K) ranks among the highest of all metals, making it exceptional at transferring heat, which is crucial for electronics, where efficient heat dissipation sets performance limits.

Its exceptional heat transfer and dimensional stability across wide temperature ranges make it essential for precision optical systems, where even microscopic distortions can degrade performance.

These properties are also exploited in beryllium oxide (BeO) ceramics, which conduct heat up to 10× better than alumina and are used in high-frequency electronics and laser systems.

Non-magnetic and Corrosion-Resistant

Beryllium exhibits negligible magnetic permeability, making it essentially transparent to magnetic fields. This is a crucial trait for gyroscopes, satellites, and medical instruments, where magnetic interference must be avoided.

When exposed to air, beryllium also creates a thin, stable oxide layer, a self-healing passivation layer. This gives it natural protection against corrosion, shielding the metal from further oxidation even in harsh environments.

These features make beryllium–nickel (Be–Ni) alloys valuable in military electronics and high-wear, non-magnetic systems.

X-ray Transparency

Most metals block radiation, but beryllium is different. Thanks to its low atomic number, it allows high-energy X-rays to pass through almost completely. That’s why it’s used in X-ray tube windows, CT scanner heads, space optics, and particle accelerators — anywhere a metal barrier must be nearly invisible to radiation.

Ionization Energy and Reactivity

Beryllium has a high first ionisation energy of 9.32 eV, which makes it relatively inert in bulk form. However, it can be chemically reactive in powdered or alloyed form, particularly when heated. This duality makes it stable in structural uses while being reactive enough for compound synthesis.

In short: Beryllium combines the lightness of plastic with the durability of engineered alloys, creating a metal modern industries simply can’t do without.

Beryllium in Action: Applications Across Industries and Everyday Life

Beryllium, a mineral of extraordinary properties, quietly underpins countless technologies that shape our modern world. From the devices in our pockets to the satellites in orbit, a unique combination of lightness, strength, and thermal stability makes it indispensable. This section delves into the surprising roles beryllium plays, first in our daily lives and then in the high-stakes world of advanced industrial technology.

Everyday and Consumer Applications of Beryllium

You won’t find beryllium listed on a product label, but chances are you’ve held it in your hands today. Hidden inside smartphones, household devices, cars, and audio systems, this rare metal plays a quiet yet essential role in the products we rely on most.

In the United States, consumer electronics and telecommunications account for nearly 45% of total beryllium consumption, underscoring its vital role in everyday technology.

Smartphones and Consumer Electronics

Modern electronics demand miniaturisation without sacrificing performance, and that’s where beryllium copper (BeCu) comes in.

- Battery contacts, vibration-resistant connectors, and spring-loaded terminals in smartphones, laptops, and tablets use BeCu for its elasticity, fatigue strength, and conductivity.

- These components endure thousands of mechanical cycles, making them ideal for high-usage gadgets.

- BeCu connectors provide exceptional mechanical resilience and high conductivity, making them ideal for smartphones, laptops, and high-performance portable electronics.

- Even your devices’ ports and charging systems likely rely on BeCu alloys for durability and low signal loss.

- As devices become smaller and more powerful, beryllium ensures they remain reliable and energy-efficient.

Telecommunications Infrastructure

Beryllium quietly supports the digital backbone of global communication:

- Undersea fibre optic cables, which carry more than 95% of the world’s internet traffic, rely on BeCu housings that resist corrosion from seawater and withstand deep-ocean pressure.

- 5G antennas and base stations use beryllium components for shielding against electromagnetic interference.

- Its thermal properties and corrosion resistance ensure signal integrity in harsh outdoor installations.

- Without beryllium, the resilience and speed of our global data infrastructure would take a hit.

Home Appliances and Everyday Devices

From your kitchen to your living room, beryllium plays a hidden role in electrical performance:

- Thermostats, microwaves, and electronic switches often contain BeCu parts that enable miniaturised and heat-stable control systems.

- High-definition televisions and routers also use beryllium-based connectors and circuitry to handle heat and maintain consistent signal flow.

- These components are often chosen for performance and long-term reliability in temperature-variable environments.

Automobiles and Electric Vehicles

Today’s vehicles rely on dozens of electrical control modules, and many of them incorporate beryllium alloys:

- Airbag sensors, anti-lock braking systems (ABS), and ignition switches often feature BeCu connectors.

- Electric vehicles (EVs) use beryllium in battery management systems and power distribution units, where heat control and electrical stability are critical.

- The material’s non-sparking, fatigue-resistant properties ensure safe operation even under repeated cycling.

Sports, Audio, and Lifestyle Products

Beryllium’s presence even extends into luxury and performance-focused consumer goods:

- High-end loudspeakers use beryllium tweeters for their exceptional stiffness and sound clarity at high frequencies.

- Especially in club faces and inserts, golf clubs have utilised beryllium copper (BeCu) for its unique feel, strength, and vibration-damping.

- Tennis racquets and premium bicycles have also incorporated beryllium or beryllium-aluminium alloys for weight savings and strength.

- In 1998, McLaren’s Formula One team famously used beryllium pistons for a performance advantage, a move later restricted by regulation.

- Whether in audio gear or automotive precision parts, beryllium adds value where reliability and high-performance matter most.

Despite its critical roles, the global beryllium market remains small, just 220 metric tonnes per year, reinforcing its status as a niche but strategically vital metal.

High-Performance Industrial Applications of Beryllium

Beyond everyday consumer items, beryllium’s extreme properties make it indispensable in sectors demanding the highest performance, precision, and durability levels.

Beryllium is commercially used in three primary forms: as a pure metal, in beryllium-copper (BeCu) alloys, and as beryllium oxide (BeO) ceramics, each tailored to different industrial demands.

Aerospace and Aviation Systems

Beryllium’s unmatched strength-to-weight ratio is critical for aerospace structures, where mass savings directly translate to better fuel efficiency and increased payload capacity.

Aircraft Components: Over 1,000 parts made from beryllium alloys are found in commercial planes, including rudders, wing boxes, and avionics housings.

Spacecraft Structures & Heat Shields: In spacecraft, beryllium’s thermal dimensional stability makes it ideal for load-bearing structures and heat shields, protecting against extreme temperature changes during atmospheric reentry and throughout space missions. NASA notably used 80-inch diameter beryllium billets for capsule heat shields and the Gemini spacecraft’s parachute system.

Advanced Optical Systems: The James Webb Space Telescope famously utilises 18 hexagonal mirrors made from gold-plated beryllium. These mirrors maintain stable optical performance across a 400°C temperature swing in the harsh vacuum of space, leveraging beryllium’s superior infrared reflectivity and dimensional stability (e.g., I-70H grade beryllium maintains stability from -196°C to 440°F).

Precision Targeting & Control: In fighter jets like the F-35 Lightning II, beryllium alloys (e.g., Beralcast®, 65% beryllium, 35% aluminium) are used in Electro-Optical Targeting System gimbal housings for precise air-to-surface targeting.

Defence and Military Hardware

Designated as a strategic material by defence ministries worldwide, beryllium is embedded in critical military and national security systems due to its rigidity, non-magnetic properties, and stability.

Missile Guidance Systems: These systems rely on beryllium for its rigidity and ability to maintain accurate targeting even during rapid directional changes, where even a 1% micron shift in the centre of mass can cause significant errors.

Advanced Surveillance & Radar: Beryllium components are used in advanced surveillance satellites and radar systems to house sensitive optics and instruments that require extreme stability under vibration and thermal cycling.

Electronic Warfare & Naval Systems: Its non-magnetic properties are crucial for naval applications and electronic warfare systems, where magnetic interference cannot be tolerated.

Lightweight Tactical Equipment: Fighter aircraft and other tactical equipment become more manoeuvrable and precise with lightweight beryllium parts, enhancing overall performance.

Nuclear Energy and Fusion Research.

Beryllium’s low neutron absorption cross-section and unique interaction with neutrons make it indispensable in nuclear technology, particularly as a neutron moderator and reflector.

Fission Reactors: It is used in fission reactors to enhance neutron economy, moderating reactor core reactions for improved efficiency and control.

Fusion Energy Programs: In cutting-edge fusion research, beryllium tiles line reactor chambers in major programs like the International Thermonuclear Experimental Reactor (ITER) and the Joint European Torus (JET). Beryllium manages plasma-facing heat and neutron flux, which is crucial for sustained fusion reactions.

Scientific Research: Beryllium-10 isotopes are valuable in climate science and cosmogenic dating, providing insights into geological and atmospheric processes.

Globally, only about 220 metric tonnes of beryllium are produced yearly, reinforcing its rarity and geopolitical importance.

High-Performance Electronics and Advanced Systems.

Beyond consumer and industrial applications, beryllium’s exceptional thermal conductivity, electrical conductivity, and durability are vital for compact, reliable, and high-speed electronic systems that power industrial and scientific breakthroughs.

Specialised Connectors & Relays: Beryllium copper (BeCu) stands out in high-performance electrical connectors for precision relays and aerospace circuits, offering significantly higher strength and fatigue resistance than standard copper alloys. This makes them ideal for maintaining reliable connections through thousands of mechanical cycles in demanding environments.

Heat Management (Beryllia Ceramics): Beryllium oxide (BeO) ceramics conduct heat up to 10× better than alumina ceramics. They are essential in power semiconductors, RF modules, and high-frequency PCBs. They effectively dissipate intense heat, allowing for smaller, more powerful processors and denser circuit designs in industrial systems and supercomputers.

Medical Imaging and Radiological Equipment

Due to its X-ray transparency, beryllium plays an often unseen yet critical role in modern medicine, particularly in diagnostic and therapeutic imaging technologies.

X-ray Windows: Thin beryllium sheets form the transparent windows in X-ray tubes, allowing radiation to exit efficiently while maintaining the necessary vacuum seal.

Enhanced Diagnostics: These beryllium windows are indispensable in advanced medical equipment like CT scanners and mammography units, enabling clearer images with reduced radiation exposure for early-stage breast cancer detection and precise radiation therapy.

Other Medical Devices: Beryllium components are also found in pacemakers and various medical laser devices, benefiting from their stability under ionising radiation and heat for reliable long-term operation.

Scientific Instruments and Advanced Detectors.

From climate modelling to subatomic physics research, beryllium supports highly sensitive and precise scientific instruments, enabling breakthroughs across disciplines.

Particle Detectors: Beryllium is crucial in neutron activation detectors for pulsed devices such as ICF (Inertial Confinement Fusion) and Z-pinch sources.

X-ray Diffraction & Spectroscopy: Synchrotron beamline windows and large-aperture X-ray TV-type detectors depend on beryllium for its transparency and rigidity, achieving high spatial resolution and dynamic range for advanced material analysis.

Environmental & Geological Research: Instruments in climate research utilise Beryllium-10 isotopes for dating glacial deposits and conducting atmospheric studies, providing valuable insights into environmental changes.

Specialised Tools and Industrial Equipment

Beryllium’s unique combination of stiffness, strength, and other properties supports precision engineering, safety-critical tooling, and high-performance industrial applications.

Non-Sparking Tools: Beryllium copper tools are highly valued for their strength and crucial non-sparking properties, making them indispensable in hazardous environments like oil rigs, chemical plants, and munitions factories where ignition prevention is paramount.

Precision Metrology: Metrology devices and high-precision lab instruments utilise beryllium for its exceptional stability under mechanical and thermal loads, ensuring accuracy in sensitive measurements.

High-End Acoustics (Industrial): In consumer products, industrial applications include specialised acoustic components. Beryllium’s high resonant frequency allows for superior sound transmission in testing equipment or very specific industrial audio solutions.

Extraction, Toxicity, and Worker Safety

While beryllium enables some of the world’s most advanced technologies, its toxicity and processing risks demand serious attention. The element’s extraction and refining involve high temperatures, reactive chemicals, and toxic dusts that pose environmental and occupational hazards if not strictly contained. Even at trace exposure levels, beryllium can trigger lifelong health effects.

This section covers the full spectrum of toxicity, from production-stage hazards to long-term worker health risks, along with evolving international regulations and industry best practices for safe handling.

Extraction and Refining Methods

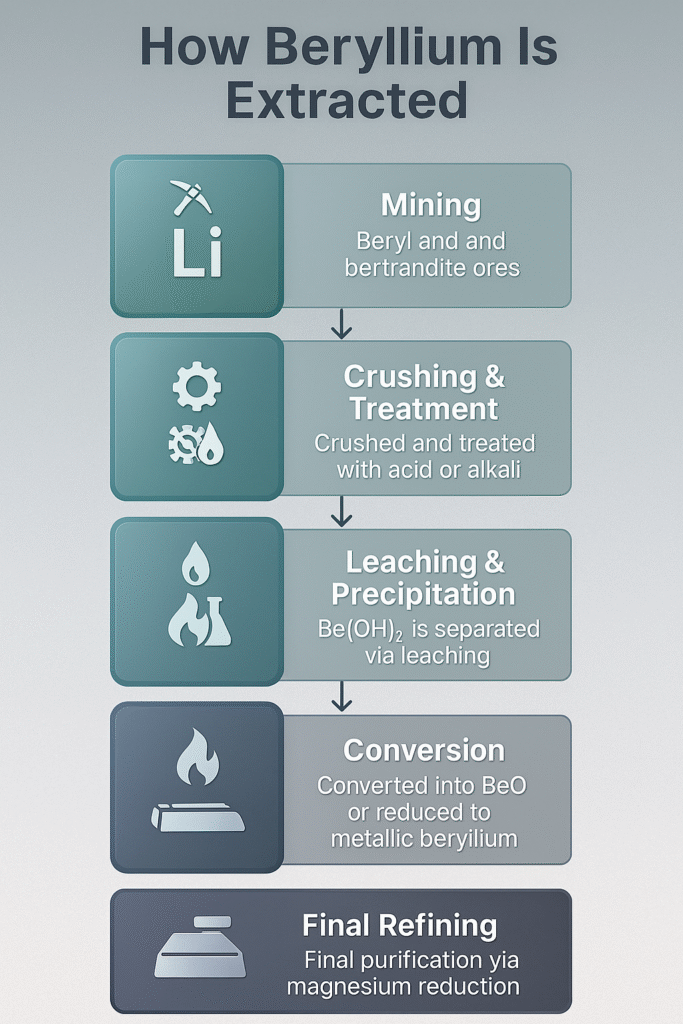

Extracting beryllium from ore is both chemically complex and safety-critical:

- Crushing and roasting: Bertrandite is crushed and treated with concentrated sulphuric acid or sodium hydroxide.

- Leaching and precipitation: Beryllium hydroxide (Be(OH)₂) is separated using selective leaching.

- Purification and conversion: The hydroxide is then heated to produce beryllium oxide (BeO) or reduced with magnesium introduced in a 75% stoichiometric quantity, to yield metallic beryllium via the thermal reduction route.

Beryllium hydroxide (Be(OH)₂) serves as the key intermediate in this process, while BeCl₂ and BeF₂ compounds also appear in nuclear-grade electrolysis due to their low melting points and ionic conductivity.

This multi-stage route is energy-intensive, and the toxic by-products require strict containment, adding to the cost and complexity. Due to the toxicity of beryllium dust and fumes, refining is done in highly controlled environments, often using proprietary methods in the U.S. and China.

Health Effects of Beryllium Exposure

Chronic Beryllium Disease (CBD), also known as berylliosis, is a granulomatous lung disease caused by immune sensitisation to inhaled beryllium particles. It primarily affects individuals with genetic susceptibility (e.g., HLA-DPB1 Glu69 alleles), and symptoms may develop years after initial exposure.

- CBD is an incurable lung condition caused by beryllium sensitisation, where the immune system reacts to even small amounts of airborne beryllium.

- Symptoms include shortness of breath, coughing, fatigue, and chest pain, which may worsen over time.

- The disease can take months or even years to manifest, making early detection difficult.

- In acute exposures, high concentrations of beryllium compounds can trigger chemical pneumonitis, an aggressive form of lung inflammation.

Beryllium Sensitisation and Diagnostic Advances

Not all exposed individuals develop CBD, but beryllium sensitisation is a critical risk factor and precursor.

- Sensitised individuals exhibit T-cell mediated immune responses even at ultra-low exposure levels.

- The Beryllium Lymphocyte Proliferation Test (BeLPT) is the gold standard for early screening and diagnosis.

- Genetic screening (e.g., HLA-DPB1 allele testing) and emerging biomarkers now allow for targeted risk mitigation in high-risk workers.

Occupational Safety Guidelines and Exposure Limits

Regulatory bodies have established stringent exposure thresholds:

- OSHA (USA): Permissible Exposure Limit (PEL) = 0.2 µg/m³ (8-hour TWA); Short-Term Exposure Limit (STEL) = 2.0 µg/m³.

- NIOSH (USA): Recommends an even lower Recommended Exposure Limit (REL) of 0.5 µg/m³.

- Controls include PPE (N95 masks, gloves), ventilated enclosures, and local exhaust systems.

International and Environmental Controls

- EU REACH: Beryllium is classified as a carcinogen and toxic by inhalation under REACH regulations.

- Mandatory workplace air monitoring, medical surveillance, and proper labeling are required in most developed countries.

- To reduce airborne contamination, industries use wet machining techniques, HEPA filters, and sealed waste disposal.

Industrial Best Practices for Safe Handling

- Negative-pressure machining enclosures prevent particle dispersal.

- Robotic arms and automation are used in high-risk environments.

- Regular BeLPT testing for employees in defence, aerospace, and ceramics industries.

- Industry training and certification (e.g., Materion Safety Modules) are used globally to reinforce compliance.

Global Production and Strategic Sources

According to the U.S. Geological Survey (USGS), the top three producers of beryllium are:

- United States – Especially Utah, home to the only operational bertrandite mine (Materion Corporation)

- China – A growing player with state-backed control over processing

- Kazakhstan – Primarily beryl-based mining

These three countries account for nearly all global primary beryllium production, narrowing the supply chain and making it geopolitically sensitive. In Russia, standard flotation concentrates contain 6.1% to 9.7% BeO a relatively higher yield compared to raw bertrandite, but still requiring significant purification steps

India’s Strategic Position and Roadmap for Beryllium

Despite its modest footprint in the global beryllium landscape, India’s need for this strategic mineral is growing rapidly. As the country expands its defence capabilities, space missions, nuclear research, and advanced manufacturing, access to secure and sustainable beryllium sources has become a strategic imperative.

Limited Domestic Reserves, High Import Dependence

India does not currently produce beryllium on a commercial scale. While beryl deposits exist in states like Jharkhand, Rajasthan, and Andhra Pradesh, extraction is not yet economically viable due to:

- Low ore concentration

- Environmental regulations

- High refining costs and safety requirements

As a result, India depends almost entirely on imports, primarily from the United States and China, for beryllium metal and BeCu alloys. This dependence introduces supply chain vulnerabilities, especially given the metal’s strategic applications.

Strategic Applications in Indian Programs

- ISRO (Indian Space Research Organisation): Beryllium is used in satellite structures, heat shields, and precision optics due to its lightweight and thermal properties.

- DRDO (Defence Research and Development Organisation): Beryllium alloys are used in missile guidance, airborne targeting, and radar systems.

- Nuclear Sector: Beryllium’s role as a neutron reflector is vital in research reactors like Dhruva and future fusion initiatives.

- Electronics & Telecom: BeCu connectors are critical to India’s ambitions in 5G infrastructure, semiconductor packaging, and defence electronics.

These applications make beryllium not just a technical requirement but a material of strategic consequence.

Policy Framework and Critical Mineral Classification

In 2023, India officially designated beryllium as one of its 30 critical minerals under the Ministry of Mines’ evolving critical minerals strategy.

- This classification was based on supply risk, economic importance, and sectoral vulnerability.

- Beryllium now falls under the policy focus of the National Critical Minerals Mission (NCMM), which aims to boost exploration, secure supply chains, and build domestic refining capabilities.

- Its inclusion alongside lithium, rare earths, and gallium signals its rising value in India’s clean-tech and defence policy landscape.

Strategic Roadmap: Securing India’s Future Supply

- Exploration: Geological agencies are re-evaluating known beryl-bearing regions for potential strategic reserves or small-scale production.

- Global Partnerships: Through KABIL (Khanij Bidesh India Ltd.), India is pursuing international agreements with the U.S., Australia, and African nations to secure critical mineral supply lines.

- Research and Substitution: DRDO and CSIR are researching safer, Be-free alloys and recycling strategies from electronic waste, though substitutes that match beryllium’s performance remain elusive.

- Stockpiling and Mandates: Discussions are underway around building strategic stockpiles of BeCu and BeO components essential for long-term defence and aerospace autonomy.

Conclusion and Outlook

From enabling deep-space exploration to powering the device in your pocket, beryllium’s impact is both broad and profound. Its ability to remain stable under heat, pressure, and radiation, while being lightweight and electrically efficient, makes it indispensable across aerospace, defence, electronics, medicine, and more.

But this critical mineral also presents significant challenges:

- Toxicity: Demands meticulous occupational controls and health safeguards

- Scarcity: Its limited natural availability and complex refining process create a narrow and geopolitically sensitive supply chain

- Lack of Substitutes: Its unique properties remain largely unmatched, especially in high-performance environments

As global demand grows, particularly with the rise of hypersonic defence systems, fusion energy research, electric mobility, and miniaturised electronics, beryllium will only become more central to the technological and strategic race among nations.

For countries like India, the path forward requires a careful balance:

- Secure foreign partnerships while exploring domestic potential

- Invest in safe processing and refining standards

- Support innovation in materials science and strategic reserves

- Recognise beryllium not just as a commodity, but as a critical enabler of national security and scientific progress

In a world increasingly shaped by material science, geostrategic competition, and supply chain resilience, beryllium stands out, not for how much we use, but for how critical even a small amount can be.

Beryllium stands out in a world increasingly defined by materials science, national security, and supply chain resilience, not for how much we use, but for how critical even a small amount can be.

As India and other nations navigate the complexities of securing essential elements for a technologically sovereign and sustainable future, what crucial steps do you believe are paramount? Share your perspective and join the vital discussion below.

This in-depth look at beryllium is just one part of the story. Continue your exploration by discovering our comprehensive series on the 30 Critical Minerals shaping India’s future.

FAQs

-

What are the main applications of beryllium in modern technology?

Beryllium is used in smartphones (battery contacts, connectors), aerospace (satellites, heat shields), medical imaging (X-ray windows), and nuclear reactors (neutron reflectors and moderators). It also appears in high-end audio, telecommunications infrastructure, and EV components.

-

Why is beryllium considered a strategic material?

Its unique combination of lightweight, high stiffness, thermal stability, and non-magnetic behaviour makes beryllium critical for defence, aerospace, nuclear, and space technologies. These properties are difficult to substitute, earning it a place on multiple countries’ strategic mineral lists, including India’s.

-

What makes beryllium unique compared to other metals?

Beryllium is six times stiffer than steel yet lighter than aluminium. It has high thermal conductivity, resists corrosion, and is transparent to X-rays. These rare traits make it indispensable in environments requiring extreme precision and durability.

-

Why is beryllium used in space telescopes like the James Webb?

Beryllium mirrors are chosen for their dimensional stability across temperature swings, infrared reflectivity, and low mass. These qualities allow telescopes like JWST to maintain perfect focus even at cryogenic temperatures in deep space.

-

How does beryllium contribute to scientific research?

Beryllium has played a role in neutron discovery and is used in particle detectors and neutron sources. Its isotope, beryllium-10, is used in climate science and geological dating to track changes across thousands of years.

-

Are there health risks associated with beryllium exposure?

Yes. Inhaling beryllium dust or fumes can cause Chronic Beryllium Disease (CBD), a severe lung condition. The metal and its compounds are also classified as carcinogens. Safety standards (OSHA, REACH) and air monitoring are required in industrial settings.

-

How is beryllium being used in emerging technologies?

Beryllium is gaining ground in renewable energy systems (e.g., solar panel efficiency), advanced manufacturing (e.g., 3D printing of precision parts), and next-gen electronics, where miniaturisation and thermal stability are paramount.

-

What must employers do to protect workers from beryllium exposure?

Employers must comply with exposure control standards such as those set by OSHA and REACH. These include maintaining airborne levels below 0.2 µg/m³, providing personal protective equipment (PPE), implementing engineering controls (ventilation, containment), conducting medical surveillance, and training workers in high-risk industries.

-

Who is most at risk of beryllium exposure in the workplace?

Workers in sectors like aerospace manufacturing, defence production, electronics, nuclear energy, ceramic processing, and precision machining face the highest risk of exposure. Even dental technicians and jewellers may be exposed when working with beryllium alloys or polishing tools.